What is FROSIO?

Corrosion protection measures and surface treatments are only effective if they are carried out by appropriately trained personnel in qualified processes.

In order to ensure the quality requirements for corrosion protection work, the organisation FROSIO was founded in Norway in 1986. FROSIO is the Council for Training and Certification of Surface Treatment Inspectors (Faglig Råd for Opplæring og Sertifisering av Inspektører innen Overflatebehandling). FROSIO has gained a high international reputation through its certification work of inspectors: A FROSIO certificate has long since become a prerequisite for many inspection activities in the field of corrosion protection.

The basic idea of the member organisation is to provide skilled workers with an understanding of holistic corrosion protection in order to ensure the quality

of corrosion protection measures of all kinds.

Therefore FROSIO promotes the quality of companies in terms of personnel and processes by testing and certifying them according to the FROSIO-GuiD-CP guideline.

Main tasks of the organisation

Definition of teaching content

Testing and certification of personnel

Approval of training bodies and audit bodies

Establishment of guidelines for companies

Certification of companies

Training and audit body HTS COATINGS

An international network of audit bodies and further education institutions work together in accordance with the FROSIO guidelines – this includes the HTS COATINGS, which has been recognised by FROSIO as a training body since 2016 and as an audit body since 2022. It is the only audit body approved by FROSIO Globally and is responsible both for auditing companies in accordance with the FROSIO-GuiD-CP and for the further training of personnel to become FROSIO coating inspectors.

What does the FROSIO-GuiD-CP regulate?

FROSIO has developed the FROSIO-GuiD-CP

(CP = Corrosion Protection) as a guideline for corrosion protection companies. It serves as a guideline

for quality management in the companies: Basic requirements for corrosion protection processes

and corrosion protection personnel are laid down here in a binding manner.

In addition, the guideline specifies how responsibilities are divided, i.e. which body in the company is responsible for monitoring and possible corrective measures. The general regulations of ISO 9001 on quality management are concretised and supplemented by the FROSIO-GuiD-CP.

Anyone who wants to make use of corrosion protection work, whether for a planned new building or the renovation of an older product, must be able to rely on the fact that the measures are carried out

in the best possible way and that the quality of the work and the end product is assured.

Certification offers you such certainty: it is a regulated process consisting of investigative activities (e.g. tests, inspections or audits), an assessment and a certification decision on whether the requirements are met. The acquired certificate serves as a neutral proof and thus creates a valuable basis of trust for

The cooperation with a certified company in the field of corrosion protection.

Contents of the FROSIO-GuiD-CP at a glance:

Establishment of essential requirements

Definition of responsibilities

Definition of the processes

Definition of monitoring and corrective measures

If the client is looking for the highest quality and durability for his project, he can adjust his requirements

to the high level of FROSIO already at the tendering stage. So if you work together with FROSIO certified companies you will achieve the best results.

In which areas is the FROSIO-GuiD-CP applied?

With FROSIO-GuiD-CP, companies, planners and designers have a valuable guideline in the field of corrosion protection which guides them in the planning, implementation and monitoring of protection and repair measures.

Which quality requirements should be set for the respective CP work? How can the quality of the corrosion protection processes best be ensured by optimal monitoring? These questions are clarified in detail in

the guideline and thus significantly supplement the quality assurance system according to ISO 9001.

Corrosion protection work by thermal spraying, duplex systems, hot-dip galvanising and coating with organic dyes are covered by FROSIO GuiD-CP. Work on new buildings is taken into account as well as renovation and repair work in the field of corrosion protection. Inspections and tests to be carried out are also specified.

Brilliant safety in all areas

Application Areas | Process Engineering | Industries |

|---|---|---|

Corrosion protection work on | Organic coatings | Bridge construction |

New buildings | Thermal spraying | On- and Offshore |

components | Hot dip galvanizing | Mechanical Engineering |

Restoration and repair work | Duplex Coating Systems | Steel construction |

Inspection and testing activities | Shipbuilding |

The all-round quality package for your project

You have found a partner company for your project in corrosion protection that is certified by FROSIO?

Then you can be sure that you are working with excellent specialists and that the necessary measures are carried out professionally. But what exactly are the services of the company carrying out the work in the field of corrosion protection covered by this certification and thus confirmed as tested?

Contract review:

A company certified by FROSIO has the necessary knowledge of contract review and can expertly assess which services are feasible.

Technical inspection:

the construction plan is examined in detail with regard to the required corrosion protection measures: Where do the corrosion protection works take place, what are the requirements and can the company meet them according to the personnel and production facilities?

Production plan:

For the manufacturing plant, a plan is prepared which details all measures to be performed and serves as a working guideline (timing, personnel requirements, material).

Corrosion protection work:

Qualified personnel (operator, process manager) is available for the work to be carried out and its quality control. The sequence of the respective corrosion protection processes is clearly specified and is observed.

Equipment & workshops:

All necessary equipment and premises for the measures to be performed are available in the certified company.

Monitoring & testing:

All work is continuously monitored and checked for quality by appropriately trained personnel.

Materials used:

Procurement, delivery, storage and handling of the materials used are documented in detail. They are carefully marked and can be traced at any time.

Tailor-made for every requirement – Certification in 3 stages

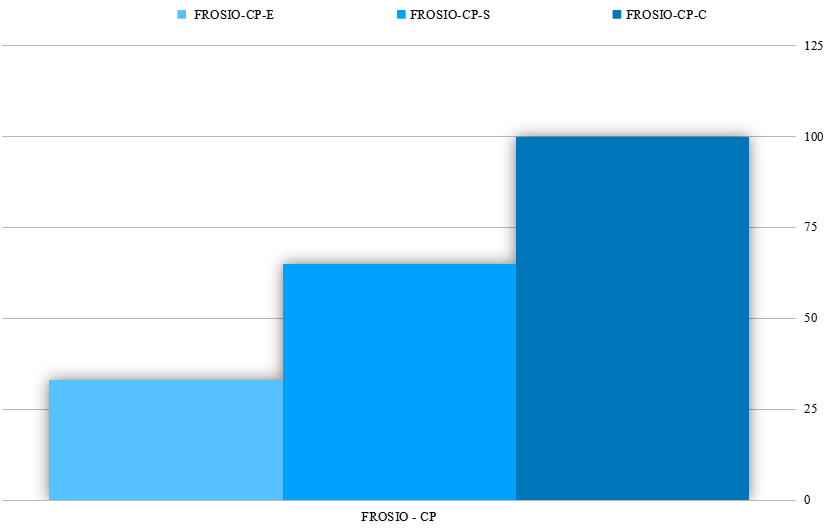

The certification of the companies carrying out corrosion protection is carried out in one of the three possible quality levels at your own choice. These are subdivided according to the scope and complexity of the various CP processes carried out in a company, the duration of protection and the expected service life of a coating until the first partial renewal is necessary.

FROSIO-CP-E

Elementary quality requirements

- Protection period under 7 years.

- Individual CP processes are carried out in your company (e.g. thermal spraying, coating or hot-dip galvanising)

FROSIO-CP-S

Standard quality requirements

- Protection period up to 15 years.

- Different CP processes are executed in your company (combination of at least two different CP processes)

FROSIO-CP-C

Comprehensive quality requirements

- Protection period over 25 years

- Different CP processes or a complete production are carried out in your company (three or more different CP processes are combined)

Identifying Certified Companies

Companies certified with the FROSIO-GuiD-CP meet the highest quality requirements for Execution of corrosion protection work: You have qualified personnel and have demonstrated suitable processes and equipment.

How can you, as a customer of corrosion protection work, find such companies quickly and easily?

FROSIO has created a database in cooperation with the auditing agency HTS COATINGS, which offers

Your advantages at a glance

Metals are indispensable as a material in many branches of industry and are used for a wide range of projects. As the durability of the processed metal is decisive for the success of the project, the expert protection of corrosion processes should be a priority for you.

Through the internationally renowned specialist council FROSIO, every client receives the assurance that

clients of corrosion protection work a search and selection option with which certified companies can be found quickly and easily.

Thus you can start with full power into a successful project with a corrosion protection you can rely on.

You can rely on this with FROSIO certified companies

Quality assurance

The normative and contractually agreed standards for corrosion protection work are observed and ensured.

Qualified personnel

The company works with highly qualified personnel, both in the execution and in the monitoring of the corrosion protection measures.

Process optimisation

Your project is realised in clearly regulated processes according to the highest requirements of corrosion protection.

International recognition

The work is carried out not only according to national but also international standards and requirements.